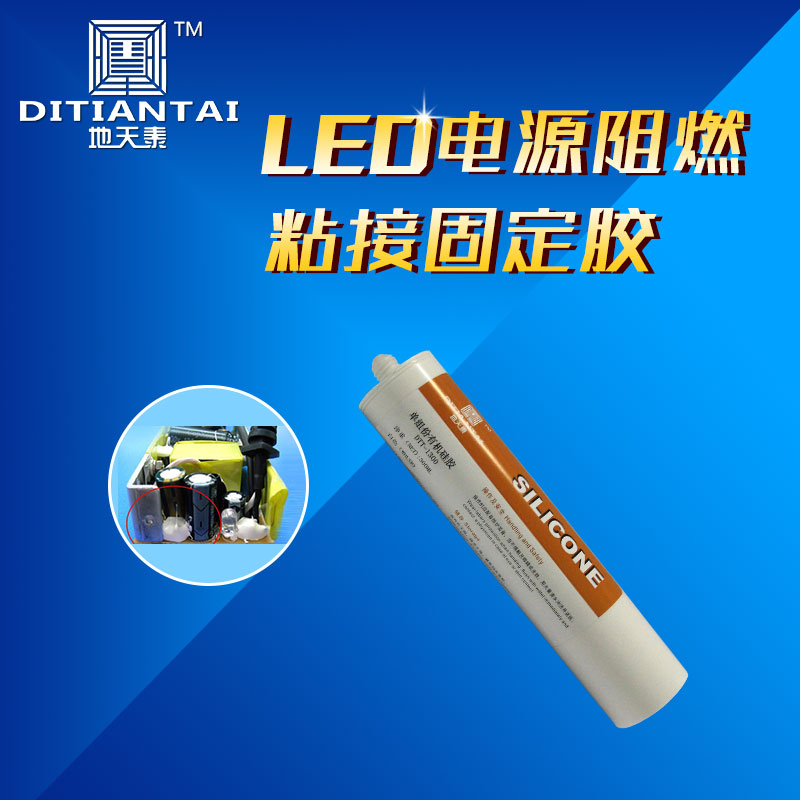

LED power source

DTT1300 is a power supply fixing adhesive, which is a single component thixotropic white neutral room temperature curable silicone rubber. It has the characteristics of environmental protection, low odor and no corrosion. It adopts advanced technology and process requirements, uses high purity imported raw materials to ensure the perfect quality of silicone rubber.

1. Thixotropic

2. Excellent adhesion to power supply substrates

3. Waterproof and moisture-proof, excellent electrical insulation performance, protect components from mechanical vibration and external force impact.

Typical uses:

Fixed power, flame retardant and heat conduction

Use process:

1. Clean Surface: Clean up the surface of the sticky or coated material, and remove rust, dust and grease.

2. Sizing: Cut off the cap of the hose, squeeze the glue onto the cleaned surface, make it evenly distributed, and close and fix the adhesive surface.

3. Curing: Place the bonded or sealed parts in the air for natural curing. The curing process is a surface-to-interior curing process. Within 24 hours (room temperature and 55% relative humidity), the adhesive will be cured at a depth of 2-4 mm. If the position of the adhesive is deep, especially where it is not easy to touch the air, the time of complete curing will be prolonged. If the temperature is low, the curing time will also be prolonged. Before further processing or packaging of the parts to be bonded, users are advised to wait long enough to keep the bonding firm and integrity intact.

Matters needing attention:

1. After the operation is completed, the unused glue should tighten the cap immediately and keep it sealed.

2. When used again, if there is a little crust at the seal, it can be removed without affecting the normal use.

3. A small amount of solidification may occur at the orifice of the adhesive during storage, and it will not affect the performance of the adhesive when it is removed.

4. The product should be stored in a cool and dry environment below 27 C for 6 months. After the shelf life, the technical indicators are still qualified and can continue to be used.

5. This kind of product belongs to non-dangerous goods. It can be transported according to general chemicals. Be careful of leakage during transportation.

Technical parameters:

固 化 前 | 性能指标 | 参考标准 | DTT1300 |

颜色 | 目测 | 白色 | |

相对密度(g/cm3,25℃) | GB/T 533-2008 | 1.62 | |

表干时间 (min℃) 冬季(11月-4月) | GB/T13477.5-2002 | 5-15 | |

表干时间 (min℃) 夏季(5月-10月) | GB/T13477.5-2002 | 3-10 | |

完全固化时间 (h) | 使用环境实测 | 24h | |

固化类型 | 使用体系实测 | 单组份醇型 | |

固 化 后 | 硬度(Shore A) | GB/T 531.1-2008 | 70±5 |

拉伸强度(MPa) | GB/T528-2009 | ≥2.4 | |

剪切强度(MPa) | GB/T7124-2008 | ≥3 | |

断裂伸长率(%) | GB/T 528-2009 | ≥50 | |

剥离强度(N/mm) | GB/T7124-2008 | 30 | |

使用温度范围(℃) | 使用环境实测 | -50~250 | |

体积电阻率 (Ω·cm) | GB/T 1692-2008 | ≥5×1014 | |

击穿强度 (kV/·mm) | GB/T 1695-2005 | ≥15 | |

介电常数 (106Hz≤ | GB/T1693-2007 | 3.5 | |

导 热 系 数 [W(m·K)] | GB/T 5598-1985 | ≥0.6 | |

阻燃等级 | GB/T 10707-2008 | 94-VO |

All mechanical and electrical properties were measured at room temperature 25 and 55% relative humidity for 7 days.

Packing specification:

100ML/120g/branch/100 branches/boxes; 300ML/445g/branch/25 branches/boxes;

2.6L/3950g/Branch/4 Branches/Box

Storage and transportation:

Such products are non hazardous goods. They can be transported according to general chemicals and be careful to leak during transportation.

- Before: Null

- After: LED power source

Chat

Chat